Is it a struggle for you to inspect and perform preventative maintenance on your overhead crane systems? Then you need Gorbel’s Maintenance Gates, designed to make it easy to service overhead crane systems with multiple bridges, and tool rail with multiple trolleys.

Many plants have crane systems with very long runways and multiple bridges. Without maintenance gates, it becomes a more complex process to add, service or inspect individual bridges. If the end trucks on a bridge in the middle of the system needs servicing, all the bridges before it on the runway as well as all of the festooning must be taken off the system in order to access that one bridge. Pulling out all of the festooning and other bridges creates a much more difficult process. A Maintenance Gate eliminates that problem by allowing access at different points along a runway.

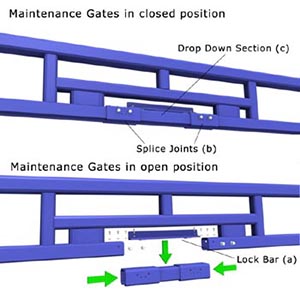

How do Maintenance Gates operate?

First, the Lock Bar (a) that keeps the Splice Joints (b) from moving into a release position must be unbolted and removed. Next, the Splice Joints (b) must be unbolted and then slid towards each other onto the Drop Down Section (c). The Drop Down Section can then be removed to create an opening. Bridges on either side of that opening can now be removed through that opening.

Gorbel® Maintenance Gates make it easier to service systems with 3 or more bridges by giving access to inside bridges without having to remove the outer bridges. This eliminates the need to remove end bridges when inspecting or servicing individual bridges in the middle of long systems. They also make it easier to install bridges on systems that have little or no space at the end of runways.

Have questions for us? Let us know!