May's Application of the Month comes to us from Florida, where a metallurgical company was feeling the pains of increased demand throughout their facility. In the heat treat area, workers unloading the treated metal simply could not move parts fast enough to keep up with demand without compromising safety or material damage.

The metal parts being moved are gears about 10 inches in diameter, and 2 inches thick. Individually, they weigh less than 5 pounds, but in order to move them quickly, they are lifted in bunches of 10‐12 pieces. Parts were being moved manually, and the higher demand paired with faster movement was a set up for operator fatigue and injury.

When the company explored solutions, a bridge crane was the obvious choice based on coverage area and ease of movement. They selected a Gorbel work station crane with multiple 500 pound bridges. The choice of a lifting device proved to be more difficult.

“We looked at traditional hoists, and it was an improvement based on the fact that people weren’t having to lift the weight,” said a company representative. “The problem was we weren’t gaining a whole lot in terms of cycle times. Operator health and safety was our top priority, and we have that now. What we need to do to make it work for us is speed up the process as well.”

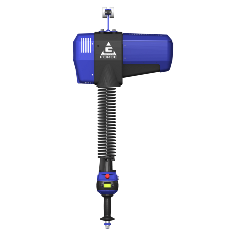

The solution came in the form of a G‐Force iQ Intelligent Lifting Device with 165 pound capacity. With lifting speeds as fast as 200 feet per minute (125 fpm loaded), the operators are able to quickly and smoothly lift and unload the hardened steel parts. Using a tool that the end user crafted, they are able to slide a spindle through the bunch of 12 gears and hook onto both ends of the spindle to lift. To unload, they set the parts down and pull out the spindle.

Check out the video here.

“It’s great, I think every factory and warehouse should have one,” said one operator. “It’s so easy.”

“The whole crane moves like an extension of my arm,” said another. “It’s as smooth as a baby’s bottom.”

While the workers were easily won over with the performance of the G‐Force, the company’s management has been thrilled that both objectives of worker safety and productivity have been achieved. While the operators are able to keep up with the increased demand without fatigue, productivity has tripled since implementing the new process.